|

||||||||

|

MAIN MENU

|

Air Pollution ControlF.P. Engineering are the Southern African arm of CTP in Austria with the rights to market and manufacture the RTO units under the CTP umbrella with the design undertaken in Austria. We together with CTP would like to introduce you to "The route to efficient air pollution control". CTP with its inhouse research division and team of highly experienced engineers is one of the leaders of pollution control in Europe and in the supply of the optimal control system for the destruction of:

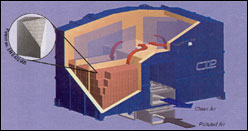

The RTO's - Regenerative Thermal Oxidizers - are designed to cope with fluctuating flows and concentrations of raw gas at lower operation costs than thermal recuperative oxidizers. The use of prismatic ceramic honeycombs in the heat exchanger enlarges the heat exchanger area three and a half times with the pressure drop in the AutoTherm remaining very low. The plant is operated by a fully automated control system. We offer a number of options on control systems, all of which are easy and safe to operate. The modular design of AutoTherms enables additional units to be added if higher efficiency or a larger capacity is required at a later date. COMPACT RTO MULTI-BED SYSTEM

High Purification rate 99.9+ %

Typical CTP multi-bed installation

New generation of compact multi-bed RTO's

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copyright � 2011 by FP Engineering. All Rights Reserved.

Website Designed & Hosted by: Cybertek